Fluid Handling Solutions

Tubes & Pipes

To ensure high-purity fluids, ASME BPE, ASTM, and DIN standards are applied for the used materials that are in contact with the product during manufacturing or storage.

These standards have different surface roughness for variant applications for avoiding fluid contamination:

- Mechanical polishing with roughness less than 0.51 microns. (SF1)

- Electro-polishing with roughness less than 0.38 microns. (SF4)

Nass Tech provides hygienic SS 316 L tubes & pipes with a range of size from 0.5 to 6 inches and DN range according to ASME BPE, ASTM, and DIN standards.

Types of pipes:

- Seamless

- Welded

All Tubes & Pipes are certified.

Fittings & Accessories

Hygienic fittings and connections are essential for the hygienic system as they help in approaching a sterile environment for the fluid by preventing any contamination.

Nass Tech provides hygienic SS 316 L fittings & accessories with a range of size from 0.5 to 6 inches and DN range according to ASME BPE, ASTM, and DIN standards:

- Fittings (Welded / Clamped).

- Elbows (90 / 45 ˚).

- Tees (Straight / Reducing).

- Reducers (Concentric / Eccentric).

- End Caps (Welded / Clamped).

All fittings are certified.

With different connections :

- Tri-clamps (Ferrules & Clamps).

- Zero Cone.

- Aseptic Flanges.

- Aseptic unions.

And providing the essential accessories:

- Rotary Spray Balls.

- Orifice Plates (Concentric / Eccentric).

- Hoses.

- Manifold.

- Gaskets (Silicon / PTFE / EPDM / Viton).

- Rupture disk.

- Manhole (Pressurized / Atmospheric).

Valves

Hygienic valves are designed to meet the highest hygienic standards. They are constructed with materials that are easy to clean and sterilize and often feature clamps or weld ends to prevent dead spaces where contaminants can accumulate.

Nass Tech provides hygienic stainless steel 316L manual & pneumatic valves according to ASME BPE, ASTM & DIN standards:

- Butterfly valve.

- Diaphragm valve (2-way and T or U types).

- Check valve.

- Ball valve.

- Angle seat valve.

- Stop & Reversing valve.

- Tank bottom seat valve.

- Safety valve.

- Sample valve

Valves are selected according to application.

All valves are certified.

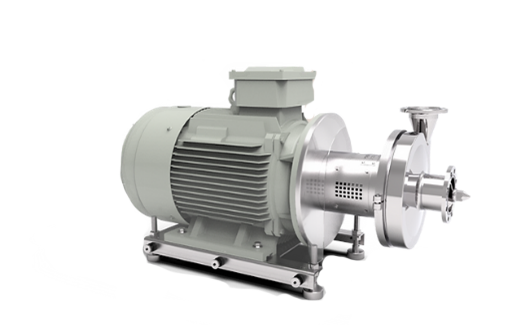

Pumps

Hygienic and aseptic pumps are types of pumps that regulate pressure, flow, and other parameters in different industries that are FDA and cGMP approved to prevent contamination of fluids.

Nass Tech provides hygienic drainable pumps which are:

- centrifugal pumps.

- positive displacement pumps.

- diaphragm pumps.

- lobe pumps.

The material of metal parts in contact with the product is SS 316 L and the external material is SS 304 with a maximum operating temperature of 120 ˚C & sanitizing at 135 ˚C for 30 minutes.

Heat Exchangers

Hygienic heat exchangers are used to transfer fluid from one temperature to another to avoid contamination. Heat exchangers could be water-to-water or steam-to-water.

Nass Tech provides SS 316 L heat exchangers according to cGMP & FDA.

Requirements for heating, cooling, or combined duty.

Types of heat exchangers:

- Shell and tube heat exchanger.

- POU heat exchanger.