Home » Business Divisions » Filtration solutions

Filtration solutions

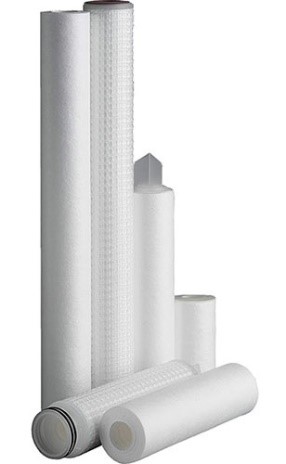

Filters

Nass Tech provides cartridge filters, capsules & filter housing in a wide variety of formats & lengths for liquids, gases & vent applications of industrial, hygienic & sanitary design in compliance with FDA & cGMP requirements.

The selection of products is due to fluid to be filtered & process conditions.

- Filter style: Melt blown, Pleated, Membrane, Capsules, Carbon, Mesh & Bag.

- Filter media: PP, PTFE, PES, Nylon, GMF.

- Micron rating: 0.03: 400 microns (Nominal / Absolute).

- Connection: DOE, Code A, Code B, Code S, C 2, 3, 6,7,8,9.

- Gasket material: Buna, EPDM, FEP, PE, Silicon, Viton, PVDF.

- Temperature: up to 200 ˚C.

- Housing material: SS 316 L / SS 304.

Applications:

- API manufacturing.

- Sterile products & IV solutions.

- Liquids, Creams & Ointments.

- Haemo-Dialysis solutions.

- Water Treatment.

- Vent & clean Gases filtration.

- Steam filtration.

- Compressed air filtration.

Membranes

Nass Tech Provides RO, UF Membranes & Pressure vessels in compliance with FDA standards.

Selection of products is due to type of water & process configuration.

RO membranes & Housing:

- Diameter: 2.5, 4 & 8 Inch

- Type: Tap water, Brackish water & Sea water.

- Salt Rejection: Up to 99.8 % TDS/Conductivity.

- Sanitization: Chemical / Hot.

- Housing Material: SS304 / SS316L / FRP.

- Pressure Range: 300:1200 PSI.

Ultrafiltration modules:

- Diameter: 6.5″ / 8.9″.

- Types: Tap water / Brackish water / Sea water.

- Micron Rating: Up to 0.1 Micron suspended solid / dissolved organic matter.

- Housing Material: UPVC.

- Pressure Range: 15:100 PSI.

EDI Modules

Nass Tech Provides electro deionizer (EDI) for producing purified & highly purified water in accordance with cGMP & FDA requirements & in compliance with international standards such as USP, EP, BP, & ISPE.

- Recovery: 90 – 95%.

- Feed Conductivity: ≤ 40 M.S.

- Feed Pressure: up to 7 BAR.

- Feed Temp: 5: 45.

- Sanitization: Chemical / Hot @ 85° C.

- Flow rate: Up to 10 m³ / h.

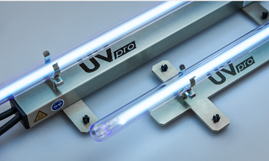

Disinfection Units

Nass Tech provides Disinfection units for both water & air according to cGMP & FDA requirements:

- Water Disinfection.

- UV Units for Process water & PW plants.

- Ozone Generator for Ultra-pure water / CIP.

- Air disinfection.

- Mobile UV Sterilizers for sterile rooms / laboratories / clean rooms.

- Vapor Hydrogen peroxide system for isolators / aseptic filling lines.

- LAF UV for micro laboratories / dispensing rooms.

- UV dechlorination.